Innovation at Light Speed, Precision Tailored Solutions

Laser SOLUTIONS,

Attending to Every Detail of Yours.

16+ Years Of Experience In The Laser Industry

For 16+ years, we’ve excelled in laser tech, mastering cutting, welding, cladding, 3D printing, and medical lasers. Our dedication to innovation and quality positions us as leaders, ready to illuminate your path with tailored solutions.

300+

Successfully Project Finished

500+

Customer Services

70%

Efficiency Improvement

95%

Customer Satisfaction

Our Services

Customized Laser Solutions

We offer customized laser solutions designed to meet your unique laser processing needs.

Upgrading Of Laser EQP

We offer upgrade and transformation services for laser equipment, giving new life to your laser devices.

Laser EQP Fault Diagnosis

We provide professional laser equipment fault diagnosis services, ensuring your production efficiency and product quality.

Laser EQP Maintenance

We offer comprehensive laser equipment repair services to ensure your devices return to normal operation as soon as possible.

Sales Of Laser EQP Parts

We offer a wide range of laser equipment accessories, including lasers, mirrors, lenses, etc., catering to various needs of laser equipment.

Laser Proofing

Our prototyping services, whether for metals, plastics, or composite materials, can meet your stringent requirements for detail and precision.

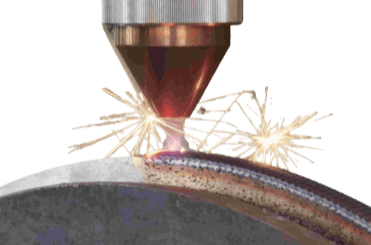

Laser Handheld Welding

Cutting, welding and cleaning 3-in-1

Capabilities

Focused & Professional & Expert

With 16+ years of deep involvement in the laser industry, we offer customized solutions, spanning applications across various fields. Integrating hardware, software, and professional services, we empower clients’ innovation and advancement, aspiring to be a leading force in the industry.

Our Projects

What Our Customers Say

Hear from our satisfied customers who have experienced the quality and value of our products and services.

Your company’s laser technology plays an irreplaceable role in our precision manufacturing processes. The high precision and efficiency of laser cutting has significantly improved the quality and production speed of our products.

Jordan Smith

The laser ceramic machining solutions offered by your company allow us to handle more complex materials and designs, bringing new life to our product line.

Taylor Johnson

The introduction of the laser medical guide arm has significantly enhanced the performance of our medical equipment, bringing patients a safer and more comfortable treatment experience.

Casey Williams

We are deeply appreciative of your team’s professional services and technical support, which have provided a solid foundation for our business success. We look forward to continuing and deepening our cooperation in the future.

Riley Brown

Request a Quote

Ready to Work Together? Build a project with us!

Learn More From

Frequently Asked Questions

3000 watts of power in cutting different materials, cutting thickness are not the same, generally carbon steel can be cut to 12mm, stainless steel can be cut to 8mm, aluminum can be cut to 6mm, brass can be cut to 4mm.

Theoretically the fiber optic slit is generally 0.02mm-0.05mm, with different optical ratios cutting the slit slightly different.

The 3000 watt power can do 60m per minute when cutting 1mm carbon steel.